Steel Grating

-

Metal Stair Treads Grating Steps For Steel Ladders

The step plate is a kind of steel grating used for stairs on the platform. According to the installation method, there are generally two types: welded and screw fixed. The side plate directly welded to the keel does not need to add the step plate. It is relatively economical and durable, but does not need to be disassembled. Thickened side plates are required on both sides of the step plate fixed by bolts, and holes are drilled on the side plate. The installation is directly fixed by bolts, which can be recycled. Customers can customize according to their actual needs, and can manufacture any type of steel grating into various sizes to match the corresponding stairs, but from the economic point of view, we recommend to use our recommended size as much as possible.

-

Trench Cover Drain Mesh Grille Steel Grating

The trench cover plate made of steel grating has a variety of models to choose from to suit different span loads and requirements. The product has the advantages of simple construction, light weight, good bearing, impact resistance, bending rather than bending, large drainage, beautiful and durable after hot-dip galvanizing, corrosion resistance, and incomparable advantages of cast iron cover plate. Hinge connection or hook connection are adopted for easy opening and anti-theft function.

-

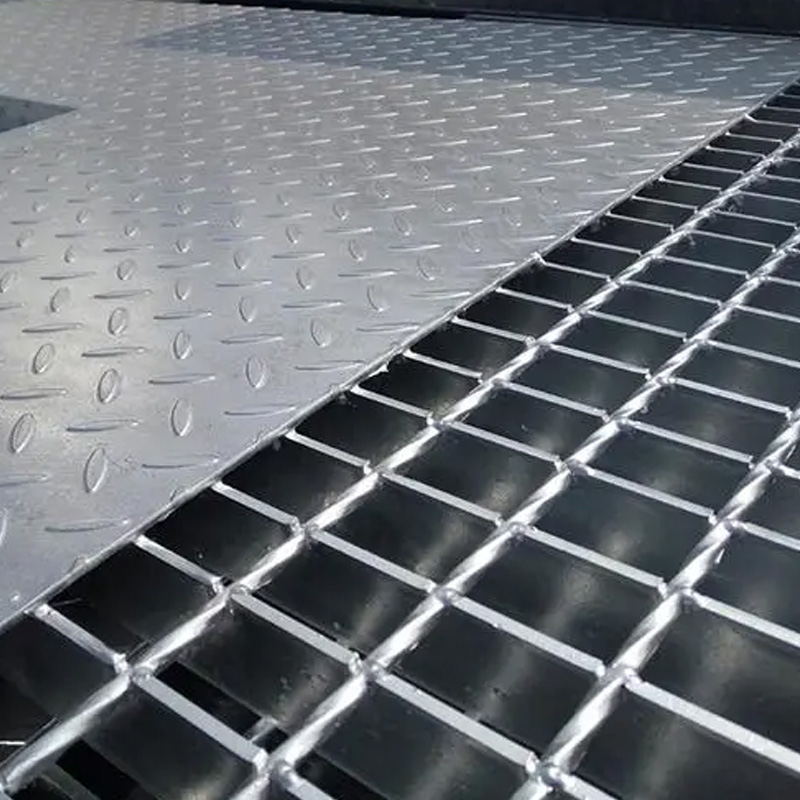

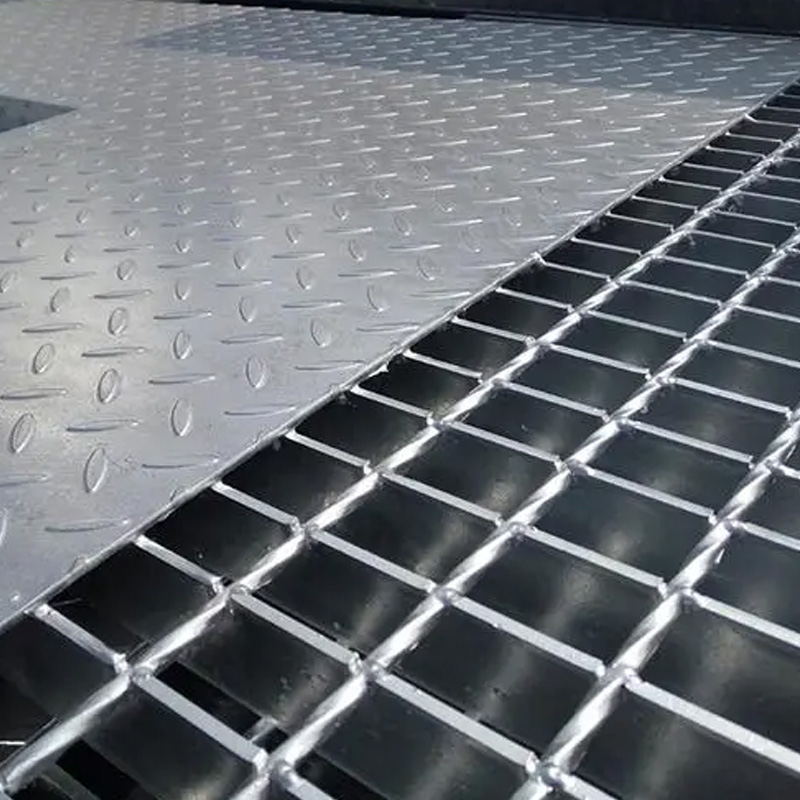

Drain Cover Galvanised Steel Grating With Checkered Plate

Composite steel grating plate is a product composed of steel grating plate with certain bearing capacity and checkered plate with sealing surface. After hot-dip galvanizing treatment, the composite steel grid plate will warp due to heat. Especially, it is difficult to level the steel grid plate with larger model. Please pay attention to the type selection.

-

Walkway Steel Grating Panel

Platform steel grating, also known as “hot-dip galvanized steel grating platform”, is a widely used steel grating product. This kind of steel grating is widely used in various fields of industry and has strong resistance to surface impact. Especially, the steel grating with a spacing of 50 mm has strong resistance to lateral impact. The application range of platform steel grating is very wide. Generally, all kinds of platforms for factory, workshop, mining, port and warehouse construction can be selected, beautiful and elegant, and easy to install.

-

High quality stainless steel sidewalk trench drain metal floor panel steel grating

Plug-in steel grating is also called pressed lock steel grating. It is a kind of steel grating distinguished according to different manufacturing methods. It is the steel grating that is fixed by pressing the cross bar into the bearing flat steel or the bearing flat steel with pre-slot through pressure at each intersection of the bearing flat steel and the cross bar. The cross bar of the press lock steel grating is usually flat steel.

-

GI Serrated Steel Bar Grating

Toothed steel grating is welded from tooth-shaped flat steel and has strong anti-skid ability. People often call it “serrated steel grating” or “serrated anti-skid steel grating”. Toothed steel grating is especially suitable for wet and greasy places, such as offshore oil production platforms. The price of toothed steel grating is higher than that of flat steel grating. Please consider the cost when purchasing.

-

Galvanized Catwalk Metal Flooring Grate Panels Flat Steel Grating

Galvanized steel grating, also known as hot-dip galvanized steel grating, is the anti-rust treatment after the steel grating is produced. It can be divided into hot galvanizing and electric galvanizing. According to the manufacturing process, hot-dip galvanized steel grating can be divided into hot-dip galvanized steel grating with pressure welding and hot-dip galvanized steel grating with pressure locking; According to the surface shape of hot-dip galvanized flat steel, it can be divided into tooth-shaped hot-dip galvanized steel, planar hot-dip galvanized steel, I-type hot-dip galvanized steel and composite hot-dip galvanized steel grating.