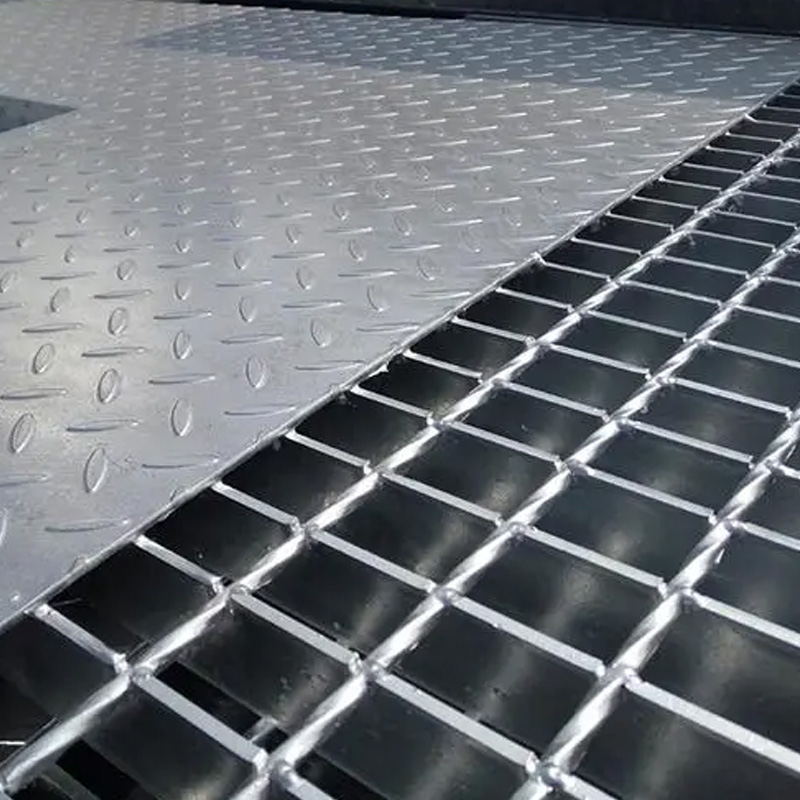

Galvanized Catwalk Metal Flooring Grate Panels Flat Steel Grating

Product Detail

Galvanized steel grating, also known as hot-dip galvanized steel grating, is the anti-rust treatment after the steel grating is produced. It can be divided into hot galvanizing and electric galvanizing. According to the manufacturing process, hot-dip galvanized steel grating can be divided into hot-dip galvanized steel grating with pressure welding and hot-dip galvanized steel grating with pressure locking; According to the surface shape of hot-dip galvanized flat steel, it can be divided into tooth-shaped hot-dip galvanized steel, planar hot-dip galvanized steel, I-type hot-dip galvanized steel and composite hot-dip galvanized steel grating. The letter "G" can be omitted from the steel grating code. The executive standard of hot galvanizing is: GB/T 13912-2002

Specification Of Galvanized Steel Grating

1. Hot-dip galvanized steel grating with flat steel spacing of 30mm is the most widely used variety in the industrial field. In the series of commonly used hot-dip galvanized steel grating, it has the strongest resistance to surface impact. The hot-dip galvanized steel grating welded by flat steel with width of 65mm - 200mm and thickness of 5mm - 20mm is applicable to large freight yards, docks, coal mines, roads, bridges, etc., and can carry large trucks through.

2. Hot-dip galvanizing (flat steel spacing 40mm) Hot-dip galvanizing steel grating with flat steel spacing of 40mm is the most economical and lightweight variety, and is the most ideal choice in the case of small span. It is suitable for various occasions, especially walkways and sightseeing platforms.

3. Hot-dip galvanizing (flat steel spacing 60mm) Hot-dip galvanizing with flat steel spacing 60mm and cross bar of 50mm is applicable to the mining industry, which solves the problem of mineral splashing on the board and is often used in the processing plant of mining industry.

The price of galvanized steel grating is determined by the width, thickness and spacing of flat steel. There are also different surface treatment methods and different prices. Generally, the price of hot galvanizing treatment is slightly higher than that of other cold galvanizing treatment and painting treatment, but it has the longest service life, and most users use this surface treatment.

Galvanized steel grating can be installed by welding and installation clamp fastening. The advantage of welding is that it is permanently fixed without loosening. The specific position is on the first flat steel at each corner of the steel grating. The weld length is not less than 20mm and the height is not less than 3mm. The advantages of mounting clips are that they do not damage the hot-dip galvanized layer and are easy to remove. Each plate requires at least 4 sets of mounting clips. The number of mounting clips increases with the increase of the plate length. The safest method is to directly weld the screw head on the beam without the lower clamp, so as to ensure that the steel grating will not slide off the beam due to the loose installation clamp.

The galvanized steel grating is beautiful in appearance and durable. The hot-dip galvanizing surface treatment makes it have good corrosion resistance and beautiful surface luster; Good ventilation, lighting, heat dissipation, anti-skid performance, and dirt prevention. It is widely used in platforms, walkways, trestles, trench covers, well covers, ladders, fences, guardrails and other fields in petrochemical industry, power plants, water plants, sewage treatment plants, municipal engineering, sanitation engineering, etc.